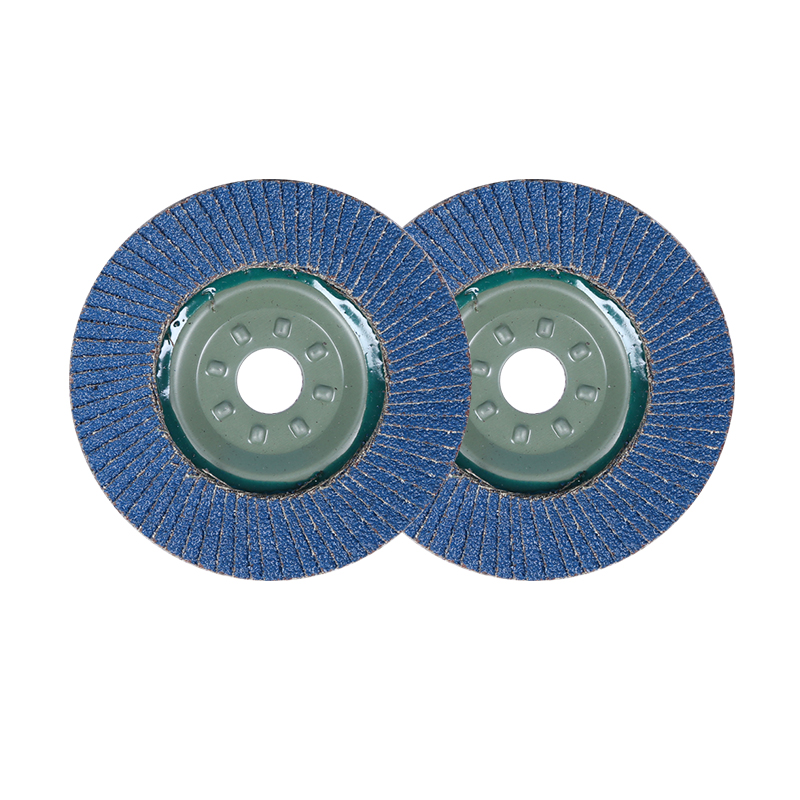

Flap disc are created by overlapping coated abrasive flaps and adhering them firmly to a back-up plate. This design provides a cooler runing,longer lasting disc.And because new layers of abrasive are constantly being exposed, a very consistent finish is provided during the life of the disc.These discs are specifically recommended for high stock removal on stainless steel,carbon steel,aluminum,and most alloys. They offer many times the life of conventional resin fiber discs. Flap Disc Feature:

1. Bonded to extremely strong but durable fiberglass or plastic backing

2.Fast , aggressive action for high-pressure grinding,high efficiency.Blending and finishing all in one operation and will reduce

process time,lower total grinding cost

4.Maximum contact with work surface with out loading

5.Consistent grinding and finishing performance

6.Excellent performance and efficiencies on stainless and carbon steel application

7.Reduce vibration and noise compared to depressed denter grinding discs

Different grain

1. Aluminum oxide: grinding and polishing, carbon steel metal,iron,cost iron, welding rods etc.

2. Zirconia: grinding stainless steel professionally etc.

3. Silicon carbide: polishing wood, copper, stone, marble,building materials,hand materials,glass etc.

4: Ceramic: Iron,cost iron, Stainless steel